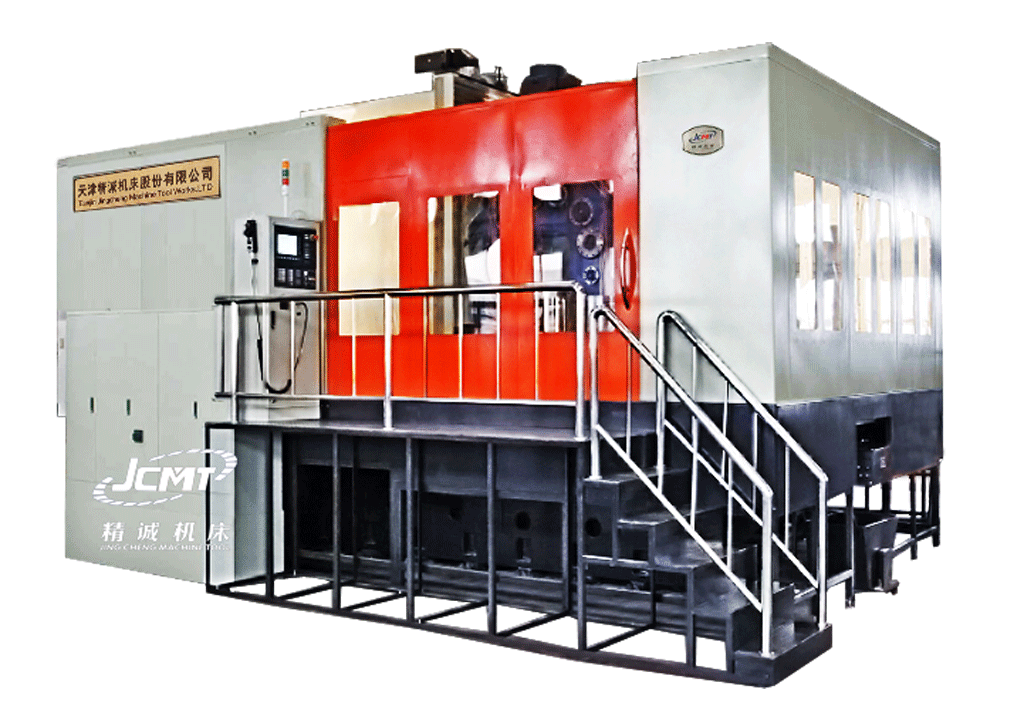

YH53 Series

Machine large module cylindrical gear, for both external and internal and both spur and helical gear. Main application area includes wind

energy, earth moving machinery, petroleum machinery, metallurgic machinery, and mining machinery.

Outstanding performance:

1.The productivity is about 20 times higher than gear shaping machine.

2.ISO1328-1997 class 8 can be reached. The surface finish is in a range of 3.2~1.6. It can meet the requirement of customer.

3.The machine with outstanding performance; Maximum tooth width is up to 500mm to machining the external helix gear. It can exceed the

gear shaping machine.

4.Energy-saving results are obvious, save a lot of purchase cost, human resource and power.

Main characteristic: advanced structure, multi-function, high standard components, high rigidity, and high productivity:

1.Machine structure gives good rigidity.

2.Machine is able to cut all kinds of cylindrical gear, which includes internal and external, spur and helical gear.

3.With Siemens 802D CNC system, machine adopts five-axis CNC system with three –axis simultaneous motion;The power of the main spindle

is 51KW. It is the largest one in this kind in China and meets the requirement of high-efficient cutting.

4.ISO1328-1997 class 8 can be reached. The surface finish is in a range of 3.2~1.6. It can meet the requirement of customer.

5.The productivity is about 20 times higher than gear shaping machine.

6.The milling head is driven by the servo motor, controlled by the system and automatically clamped with spring device.

7.The milling head has two spindles. Within certain range, the machine is able to machining internal and external gear without changing the

milling head.

8.To extend the cutting range of external gear, an external milling head is available as an optional.

9.The machine has a lots of Human Design function. The machine is equipped with fully protected on top open so that ensure the safety of

operator. The machine is a full CNC machine. All controls are done by the control panel. It is environment friendly with dry cutting, no coolant oil is needed. Therefore there will be no smoke or mist during cutting. The chip will come out from the hole in the middle of the worktable. Then the chip conveyor will take the chip to the trolley. This system reduces the workload of the operator and gives better safety.

Parameter table:

Design sketch:

086-022-24981179

086-022-24981179